When it comes to bridge inspection equipment, the variety of underbridge inspection units can be somewhat overwhelming.

Not only is there a wide range of different types of machinery available, but among these types, there is a large range of sizes to choose from. The type of underbridge inspection unit used is largely dependent on the type of bridge inspection, the height of the bridge, and the location.

Underbridge Inspection Units: How Low Can You Go?

Among the variety of booms and lifts that make up underbridge inspection unit equipment, scissor lifts are typically on the “low” end of the scale in terms of reach. For example, when accessing the underside of low bridges, scissor lifts may be used for bridge inspections with low clearance between the bridge and underpassing roadway.

Scissor lifts have a typical maximum vertical reach of 20 feet. These lifts are designed for use on relatively level ground and have obvious limitations in terms of overall reach.

Aerial boom lifts are commonly used for bridge inspections and these, too, are engineered in a wide variety of types. On the small end of the range of telescopic, or straight, boom lifts you can find machines that only have a 35 foot vertical reach. This is almost double the minimal reach of a drivable scissor lift, but still relatively short.

When it comes to articulated boom lifts, also known as “knuckle lifts”, are typically used for accessing the underside of bridges either from directly underneath, or “over and under” from a bridge deck. However, even these can be relatively small.

It is possible to access articulated boom lifts, or aerial man-lifts, with only a 30 foot vertical reach.

Reaching New Heights

The other extreme for underbridge inspection units and aerial lifts is both height and reach.

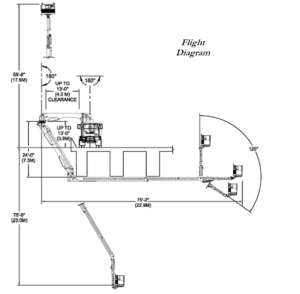

Currently, the largest self-propelled boom lift is manufactured by JLG Industries. The Model 1850SJ Ultra Boom has a 185-ft. platform height which is equivalent to almost 20 stories. In addition, with its 360 degree swing access, it can offer up to 80 feet of horizontal reach, as well.

While it does have one articulated joint to keep the working platform level, it is still considered a straight, or telescopic, boom lift. There are also massive, fully articulating boom lifts that also offer extreme height access.

In fact, the same company makes the tallest and farthest reaching articulating boom lift with a working height of 60 feet and a 360 degree, 77 foot working outreach. However, there is a family of truck mounted underbridge inspection units designed to operate from a bridge deck that can also reach incredible distances.

The Aspen A-75 is the largest of the under bridge machines with a 75 foot maximum horizontal reach. The A-75 also provides 16 feet of vertical reach with a fourth telescopic boom section. This monster of a machine enables bridge inspectors and maintenance operators to access virtually any location on wide bridges.

The articulated boom design provides versatile access around bridge members and lighting supports, as well as over fences, barriers, across wide sidewalks and walkways, between cables and trusses, and behind bridge girders.

Choosing the Right Size

While these machines are available in extremely “small” sizes, as well as “monster truck” versions, like the A-75, the type and size you need for your own inspection job likely falls somewhere in between.

One of the things you want to avoid is to rent a machine that is too big for the job at hand. Opting for an oversized boom lift may actually limit your access unnecessarily. If you are accessing an underside of a bridge, for example, and the area underneath is particularly narrow or has limited working space, using a smaller, lower-reach boom lift or even a lightweight motorized scissor lift may be more efficient than a large articulated boom lift.

Smaller lifts designed specifically for lower heights will be easier to maneuver and have minimal impact on your working environment. This makes them a better option for lower bridges. However, if you need to work on rough terrain, using a slightly larger, more powerful machine will ensure accessibility and mobility.

Also, renting a machine that is far larger than you need can unnecessarily increase your costs due to the price of renting a larger unit and the fuel and other maintenance costs.

On the other hand, it can be both inefficient and even dangerous to not have a large enough machine for your inspection, cleaning or maintenance project. A machine that is too small for the job can cause you to go over time and over budget because it takes longer to accomplish the tasks you need to get done.

The platform size and capacity matters, as well. Take time to consider how many workers and what kinds of tools and materials you need to support with your underbridge inspection unit before selecting a machine. A machine of the appropriate height reach and platform capacity will allow you to carry everything you need and cover more work area in fewer trips than using a machine that’s too small.

Also, consider the surface or terrain your underbridge inspection unit will be situated on and traveling over. It’s critical to ensure you’ll have sufficient horsepower and the proper tires to handle any surface conditions you may encounter. Contact us for more information.

Recent Comments