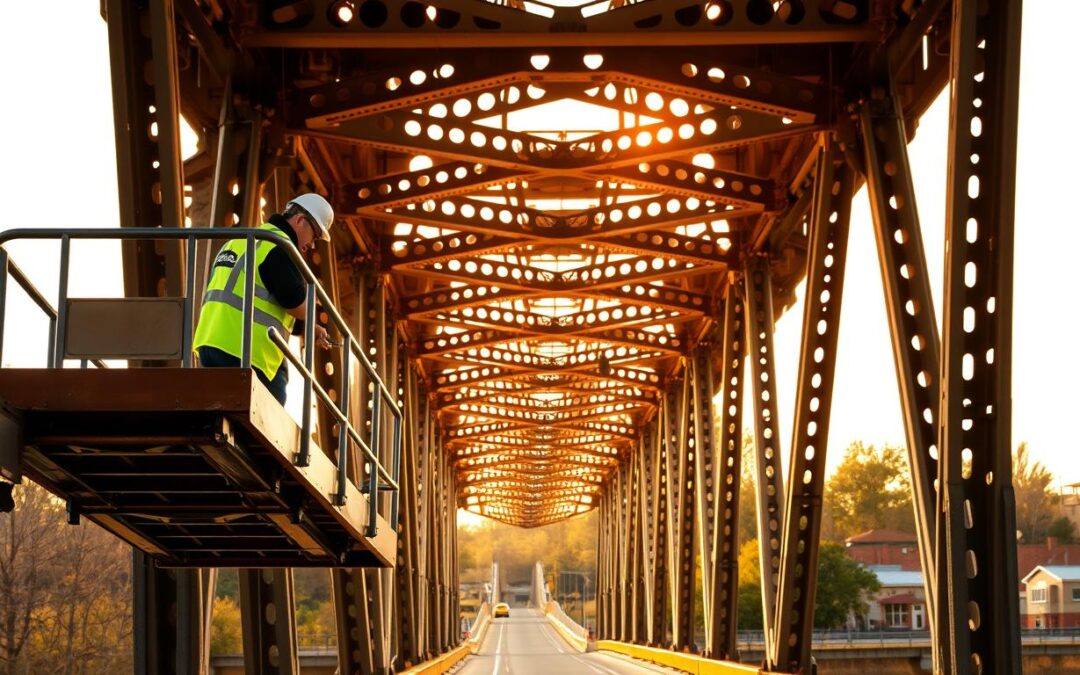

How can inspectors and maintenance crews efficiently and safely access the complex structures of truss bridges?

Truss bridges are complex and hard to inspect and maintain. They have many parts and it’s hard to get to them. Specialized equipment is needed to keep these bridges safe and strong.

Articulating under bridge platforms solve these problems. They give safe and easy access to the underside of truss bridges. This makes inspections and maintenance work better.

Key Takeaways

- Truss bridges require specialized equipment for inspection and maintenance.

- Articulating platforms enhance safety and efficiency.

- Access limitations are a significant challenge.

- Specialized platforms facilitate thorough inspections.

- Safe access improves maintenance outcomes.

The Unique Challenges of Truss Bridge Inspection and Maintenance

Inspecting and maintaining truss bridges is a tough job. This is because of their complex shapes and many connection points. They need regular checks to stay strong and last long.

Structural Complexity of Truss Designs

Truss bridges have complex designs with many parts connected together. This structural complexity makes finding problems hard without careful inspections.

- Multiple load-bearing components

- Intricate connection points

- Varied geometric configurations

Access Limitations in Traditional Inspection Methods

Old ways of inspecting, like scaffolding or rope access, are slow and risky. They also can’t reach all parts of the truss bridge.

Using these methods can cause:

- Longer inspection times

- Higher costs for labor and equipment

- More danger for the inspectors

Safety Concerns for Inspection Personnel

Keeping inspectors safe is a big worry with truss bridges. They often have to work high up and in tough spots, raising the chance of accidents.

Some major safety worries are:

- Falls from heights

- Equipment failure

- Bad weather

Understanding Articulating Under Bridge Platforms

Articulating under bridge platforms have advanced mechanical systems. They give unique access to truss bridges. This changes how we inspect and maintain these structures.

These platforms use core technology for precise movement. This lets inspectors safely reach hard-to-access areas of truss bridges.

Core Technology and Mechanical Design

The mechanical design of these platforms includes advanced hydraulic systems and arms. This design allows for flexibility in navigating truss bridges’ complex shapes.

Types of Articulating Platforms Available

Articulating under bridge platforms vary to meet different inspection needs. The main types are:

- Truck-Mounted Systems: These are on trucks, making them easy to move to different bridge locations.

- Self-Propelled Units: With their own propulsion, these units can handle tough terrain. They’re great for remote or hard-to-reach areas.

Truck-Mounted Systems

Truck-mounted systems are versatile. They can quickly move to various sites. This makes them good for many bridge inspection tasks.

Self-Propelled Units

Self-propelled units can go where traditional systems can’t. They offer more flexibility in planning inspections.

Evolution from Traditional Access Methods

The creation of articulating under bridge platforms is a big step forward. It’s safer, more efficient, and cheaper than old methods like scaffolding and rope access. It’s a better way to inspect and maintain truss bridges.

How Articulating Under Bridge Platforms Transform Truss Bridge Maintenance

Articulating under bridge platforms are changing how we inspect and maintain truss bridges. They offer a safer and more efficient way to access these complex structures. This is a big step up from older methods.

Navigating Complex Geometric Configurations

These platforms are made to handle the tricky shapes of truss bridges. Their flexible articulating arms let inspectors get to hard-to-reach spots. This way, they can do thorough checks without risking their safety.

Accessing Hard-to-Reach Connection Points

Articulating under bridge platforms are great at getting to spots that are hard to reach. They provide a stable place for maintenance workers to do their jobs. This makes their work safer and more efficient, cutting down on the chance of accidents.

Adapting to Various Truss Designs and Dimensions

These platforms can fit many different truss bridge designs and sizes. They can adjust to fit historic or modern bridges. For example, the Aspen UB-60 shows how versatile they are. To learn more about picking the right platform, check out Understanding Load Capacities and Reach.

Safety Enhancements Through Modern Platform Technology

Modern platform technology has made truss bridge maintenance safer. Advanced safety features in articulating under bridge platforms have cut down risks. This is true for both inspection and maintenance tasks.

Operator Protection Systems

Today’s articulating under bridge platforms come with top-notch operator protection systems. They have fall arrest systems, personal protective equipment (PPE), and ergonomic designs. These help reduce operator fatigue.

For example, platforms in articulated aerial equipment offer better stability and control. This protects operators during tricky maneuvers.

Stability Features for High-Wind Environments

Articulating under bridge platforms now have special stability features for high winds. They include wind sensors that warn of dangers and mechanical stabilizers for better stability. These are key for safety in windy or bad weather.

Emergency Response Capabilities

Modern platforms also have emergency response capabilities. They have emergency descent systems, rescue winches, and communication tools. These help respond fast in emergencies, keeping operators safe.

With these advanced safety features, articulating under bridge platforms make work safer. They ensure a safer work environment and lower accident risks.

Efficiency and Economic Benefits of Specialized Access Equipment

The use of articulating under bridge platforms has changed truss bridge maintenance a lot. It brings big efficiency benefits and economic benefits. These platforms make inspections faster and cheaper, saving money on maintenance.

Reducing Inspection Timeframes

Articulating under bridge platforms make inspections quicker. They give direct access to truss parts. This efficiency means teams can finish their work faster, saving on labor costs and cutting down on traffic delays.

Minimizing Traffic Disruption Costs

These platforms let inspections and maintenance happen quickly and with less impact on traffic. This is great for busy bridges, where long closures or lane restrictions can cost a lot.

Long-term ROI for Infrastructure Agencies

Investing in articulating under bridge platforms can pay off big time for infrastructure agencies. They help cut down on the cost and frequency of inspections and maintenance. This leads to better, more affordable bridge care over time.

| Benefits | Description | Impact |

|---|---|---|

| Reduced Inspection Time | Direct access to truss components | Lower labor costs |

| Minimized Traffic Disruption | Swift inspections and maintenance | Reduced economic losses |

| Long-term ROI | Sustainable bridge management | Cost-effective maintenance |

Implementation Strategies for Truss Bridge Inspection Programs

Creating a good truss bridge inspection program takes careful planning. It’s important for keeping bridges safe, efficient, and affordable to maintain.

Equipment Selection Guidelines

Picking the right tools is key for truss bridge checks. Articulating under bridge platforms are great for tricky truss shapes. Think about the truss design, bridge size, and what you need to inspect.

Crew Training Requirements and Certification

It’s vital to train and certify inspection teams well. They need to know how to use special gear, follow safety rules, and collect data. Keeping certifications up-to-date helps them use the latest methods and tools.

Integrating with Comprehensive Bridge Management Systems

Good truss bridge inspection plans should link up with bigger bridge management systems. This helps manage inspection data, plan maintenance, and use resources wisely. For more on bridge management, check out the Transportation Research Board’s publications.

| Implementation Aspect | Description | Benefits |

|---|---|---|

| Equipment Selection | Choosing the right inspection tools for the truss and bridge size. | Boosts safety and accuracy. |

| Crew Training | Offering full training and certification for inspection teams. | Makes them more efficient and safer. |

| System Integration | Linking inspection data with big bridge management systems. | Improves data handling and maintenance planning. |

Case Studies: Articulating Under Bridge Platforms in American Infrastructure

Across the United States, case studies show how articulating under bridge platforms help. They preserve historic truss bridges and keep modern highway trusses in good shape. These examples prove the technology’s effectiveness and flexibility in different projects.

Historic Truss Bridge Preservation Projects

Keeping historic truss bridges safe is a big challenge. Articulating under bridge platforms are key to this effort.

The Golden Gate Approach Spans

The Golden Gate Bridge’s approach spans have been checked and fixed with these platforms. This has helped keep the bridge strong and lasting.

In Pennsylvania, historic truss bridges have also been helped. The platforms let maintenance teams safely and easily reach and fix the bridges’ complex parts.

Modern Highway Truss Maintenance Programs

Articulating under bridge platforms are not just for old bridges. They’re also used for new ones. They help reach and maintain the complex shapes of modern truss bridges, keeping them safe and working well.

Conclusion: Embracing Innovation for Safer, More Efficient Bridge Infrastructure

Using articulating under bridge platforms is a big step up in bridge care. It makes both safety and work more efficient. For example, the Hangzhou Bay Bridge and the Henderson Waves Bridge show how complex designs need careful checks.

Articulating under bridge platforms make it easy to get to hard spots. This is key for keeping these complex structures safe and sound.

With under bridge inspection platforms, maintenance teams can save money and time. They can also make bridges last longer. This means big savings over time, thanks to better efficiency and lower costs.

It’s clear that embracing new ideas in bridge care is essential. It helps keep bridges safe and makes inspections more effective.

Recent Comments