High winds are a big challenge for bridge safety assessments, mainly during under bridge inspections. It’s interesting to know that almost 40% of bridge collapses happen because of issues found during regular checks.

The safety of under bridge platforms is key for both inspectors and the quality of assessments. Underbridge inspection technology has improved, but high winds are a big problem for inspectors.

It’s important to plan and do under bridge inspections well, even when the weather is bad. This means knowing how high winds affect inspection platforms and using the best methods to keep them stable.

Key Takeaways

- High winds significantly impact the stability of under bridge inspection platforms.

- Advanced underbridge inspection technology can mitigate some risks associated with high winds.

- Proper planning is key for safe and effective under bridge inspections.

- Inspectors must be aware of the challenges posed by high winds to bridge safety assessments.

- Best practices for under bridge inspections can enhance platform stability during high winds.

The Challenges of High Wind Conditions in Bridge Inspections

High winds make bridge inspection services harder. They need careful planning and execution for safety and accuracy. Inspectors face tough environmental conditions that can shake inspection platforms and put people at risk.

Wind Speed Thresholds and Their Impact on Inspection Operations

Knowing wind speed limits is key for deciding when to do bridge maintenance evaluation in windy weather. Wind speed affects the safety and success of inspections.

Measuring Wind Speed at Bridge Sites

It’s important to accurately measure wind speed at bridge sites. This helps decide if inspections should go ahead or wait. Anemometers give real-time wind speed data.

Operational Limitations Based on Wind Velocity

Wind speeds set different limits for operations. For example, strong winds can make it hard to safely use inspection tools. This limits how well a structural integrity assessment can be done.

| Wind Speed (mph) | Operational Impact | Safety Concerns |

|---|---|---|

| 0-20 | Minimal impact on operations | Low safety risks |

| 21-40 | Moderate winds; some operational challenges | Moderate safety risks |

| 41+ | Significant operational limitations | High safety risks |

Safety Risks Associated with High Winds

High winds pose big safety risks during bridge inspections. These include personnel safety concerns and equipment stability issues. Inspectors must know these risks and take steps to avoid them.

Personnel Safety Concerns

Inspectors face dangers like being knocked off balance or hit by flying objects in high winds. Keeping inspectors safe is the top priority.

Equipment Stability Issues

High winds can make inspection tools unstable. This could lead to accidents or damage. Regular checks and ways to keep tools stable are vital.

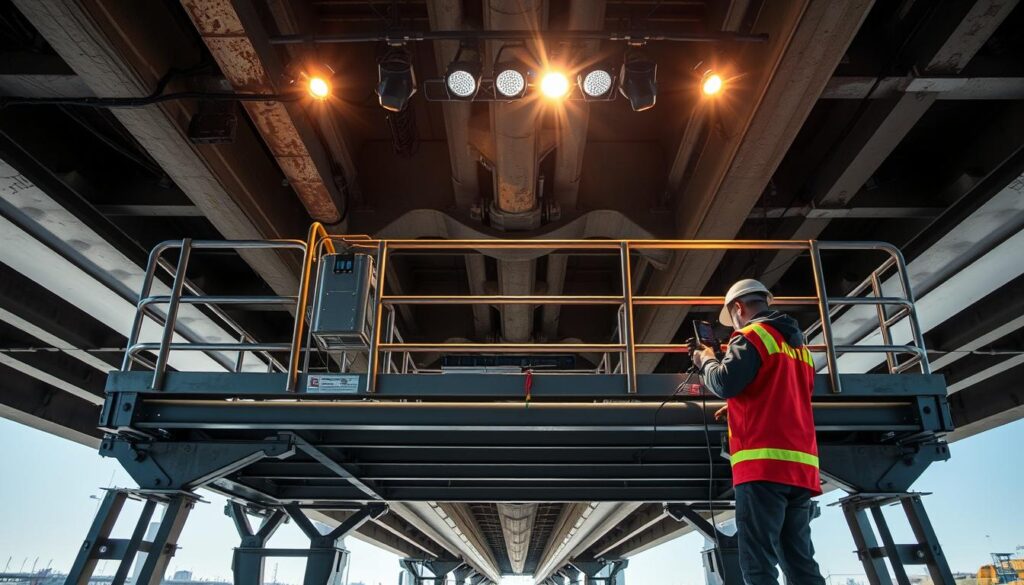

Understanding Under Bridge Inspection Platforms

Under bridge access equipment has changed a lot to meet the needs of complex bridge inspections. These platforms give safe and easy access to the underside of bridges. This lets inspectors check the structure’s condition.

Types of Under Bridge Inspection Units

Under bridge inspection platforms vary to fit different inspection needs. The main types are:

- Truck-Mounted Access Platforms: These are stable and mobile, perfect for moving around a lot.

- Self-Propelled Units: They are flexible and can handle tough terrain, great for many bridge types.

- Trailer-Mounted Systems: Used for certain bridge setups, they offer a flexible solution for inspections.

Platform Design Features for Wind Resistance

The design of under bridge inspection platforms includes features for better wind resistance. This ensures safe use even in bad weather.

Aerodynamic Considerations

Aerodynamic design is key in reducing wind’s effect on platforms. It helps keep the platform stable and safe for inspectors.

Structural Reinforcements

Along with aerodynamics, structural reinforcements boost the platform’s stability. These help stand up to strong winds and keep the platform solid.

Pre-Inspection Planning for Windy Conditions

Planning before a bridge inspection is key to safety and success, even in bad weather. This step includes several important parts. They work together to reduce risks from strong winds.

Weather Forecasting and Monitoring

Knowing the weather is vital for planning bridge checks. Reliable weather info sources give us wind speed and other weather data.

Reliable Weather Information Sources

It’s important to use trusted weather forecasts. These forecasts help bridge inspection companies plan safely.

On-Site Weather Monitoring Tools

Weather tools on-site give real-time wind data. This lets inspectors decide if it’s safe to inspect or not.

Risk Assessment Protocols

Doing detailed risk assessments is critical. It helps spot dangers from high winds. This includes wind-specific hazard identification and making safe decisions.

Wind-Specific Hazard Identification

Inspectors need to find hazards like unstable platforms and falling objects. High winds also reduce visibility.

Go/No-Go Decision Making Process

A clear process for deciding to inspect or not is essential. It’s based on the risk assessment.

Developing Contingency Plans

Having backup plans is vital for managing risks. These include emergency evacuation procedures and rescheduling rules for bad weather.

Emergency Evacuation Procedures

Good emergency plans ensure quick action in changing weather.

Inspection Rescheduling Guidelines

Clear rules for rescheduling help bridge inspection companies manage during bad weather.

By planning well, bridge inspection reports can be done safely, even in windy weather.

Best Practices for Under Bridge Inspections During High Winds

Keeping under bridge inspections safe during high winds is key. Inspectors need the right tools and knowledge. This helps them face the challenges of windy conditions.

Stabilization Techniques for Inspection Platforms

Keeping the inspection platform stable is very important. This means using several important techniques:

- Outrigger Positioning and Setup: Setting up outriggers right can make the platform much steadier. Inspectors should make sure outriggers are firmly placed on solid ground. This helps fight against the wind’s force.

- Counterbalance Weight Distribution: It’s important to spread out counterbalance weights well. This keeps the platform balanced. Inspectors need to adjust these weights based on the wind and the platform’s shape.

Communication Protocols for Inspection Teams

Good communication is key for inspection teams, even more so in windy and noisy places. Two main points are:

- Hand Signals for Noisy Conditions: Using standard hand signals helps team members talk when it’s hard to hear.

- Radio Communication Best Practices: Using radios that cut down wind noise and having clear rules for talking helps teams work better together.

Safety experts say, “Good communication is the heart of any successful inspection, even more so in tough weather.”

Emergency Response Procedures

Even with careful planning, emergencies can happen. It’s vital to have good emergency plans ready:

- Platform Retrieval During Sudden Wind Gusts: Inspectors should know how to quickly and safely pull back the platform if a strong gust hits. This reduces the chance of accidents.

- Personnel Evacuation Techniques: Sometimes, getting people out fast is needed. Regular practice and clear plans are key for a quick and safe move.

By following these best practices, inspection teams can make under bridge inspections safer and more effective during high winds. This helps keep bridges safe and sound.

Equipment Modifications and Adaptations for Windy Conditions

Equipment changes are key to making under bridge inspections safer and more effective in windy weather. To deal with high winds, teams can make several adjustments to their gear.

Wind Shields and Barriers

Wind shields and barriers help lessen the wind’s effect on inspection platforms. They can be set up temporarily or be a permanent part of the platform.

Temporary Wind Screens Installation

Temporary wind screens can be placed around the platform to block wind. These screens are easy to put up and take down, making them handy for different wind levels.

Permanent Platform Modifications

For places that are always windy, making permanent changes to the platform is a good idea. This includes adding wind shields or barriers into the platform’s design. It makes the platform more stable.

Counterweight Systems

Counterweight systems are vital for keeping inspection platforms steady in windy weather. The right counterweights can greatly lower the chance of the platform tipping over.

Calculating Proper Counterweight Requirements

To figure out the right counterweight, you need to look at the platform’s design, expected wind, and the weight of people and equipment. Getting this right is key to keeping the platform stable.

Adjustable Ballast Systems

Adjustable ballast systems let inspectors change the counterweight as wind changes. This flexibility is very useful when wind speeds can change a lot during an inspection.

Advanced Stabilization Technologies

There are also new technologies that can make platforms even more stable. These use advanced engineering to adjust the platform’s stability in real-time.

Hydraulic Stabilization Systems

Hydraulic systems use hydraulic actuators to adjust the platform’s stability in real-time. They help keep the platform steady, even when the wind moves it.

Computer-Assisted Platform Leveling

Computer systems help keep the platform level, even in windy weather. They use sensors and algorithms to adjust the platform’s level, keeping it stable and secure.

By using these equipment changes and adaptations, under bridge inspections can be done safely and effectively, even in windy weather. This makes the inspections safer for the team and more accurate and reliable.

Regulatory Compliance and Industry Standards

Following regulatory frameworks is key for bridge safety assessments, mainly in windy areas. It ensures that bridge inspection companies keep safety and accuracy at the highest levels.

OSHA Requirements for High Wind Operations

The Occupational Safety and Health Administration (OSHA) sets rules for working in windy conditions. Bridge inspection companies must follow these to keep their work environment safe.

Wind Speed Work Restrictions

OSHA says work must stop when winds get too high to avoid accidents. For bridge inspections, inspectors must watch wind speeds and stop work when needed.

Documentation and Reporting Requirements

It’s vital to have accurate bridge inspection reports for following rules. Inspectors need to record all inspection details, including weather, and submit reports as needed.

NBIS Guidelines for Adverse Weather Inspections

The National Bridge Inspection Standards (NBIS) offer more advice for inspections in bad weather. They stress the need for quality assurance in tough conditions.

Quality Assurance During Challenging Conditions

Inspectors must use strict quality control to make sure bridge safety assessments in windy conditions are valid. This means checking the accuracy of data and the working of equipment.

Inspection Validity and Certification

An inspection is valid only if it meets NBIS standards. This includes the certification of inspectors and following set protocols for bad weather.

The table below shows important rules for bridge inspections in windy weather:

| Regulatory Body | Guideline | Description |

|---|---|---|

| OSHA | Wind Speed Work Restrictions | Halting work during high winds to prevent accidents |

| OSHA | Documentation and Reporting | Accurate reporting of inspection details and weather conditions |

| NBIS | Quality Assurance | Ensuring inspection validity through rigorous quality control |

| NBIS | Inspection Validity and Certification | Compliance with guidelines for valid and certified inspections |

Conclusion: Ensuring Safe and Effective Bridge Inspections in Challenging Conditions

To keep bridge inspections safe during high winds, we need a few key steps. These include careful planning, the right tools, and following the best practices and rules.

Knowing how high winds affect inspections is key. Using the right under bridge inspection platforms helps teams stay focused. Planning before the inspection, like checking the weather and assessing risks, is also important.

Using the best methods and adjusting equipment as needed helps a lot. It’s also important to follow safety rules, like those from OSHA and NBIS. This ensures the inspection is done right and safely.

By sticking to these steps, teams can keep everyone safe and get accurate results. This makes bridges safer and more reliable, even when the weather is tough.

Recent Comments